CEPAT AG was founded in 1992 in Chur, which is located in the canton Graubünden in Switzerland and has set the task of providing need-based thermoplastics to customers in the technical area with focus on the automotive industry. We focus on granules which can be processed in modern melt-print systems. Customers’ demands are carefully examined in order to develop and deliver the products according to their needs. Through specialization and restriction on thermoplastic products we have reached an outstanding competence in this narrow area.

This competence will be expanded continuously and leads to a marked leadership in the automotive sector through a constant quality improvement.

We offer a great range of thermoplastic products sold throughout the world under the commercial name Cepatex and are continuously developing new products to satisfy the shifting needs of the market.

We want to use our experience and know-how combined with the outstanding quality of our specially designed products to improve our leading market position in the automotive industry and to further concentrate on special textile applications.

CEPAT AG provides copolyesters, copolyamides and polyester elastomers commercialized under the name Cepatex. Our portfolio comprises a large range of products with a great variety of physical properties.

All Cepatex Products are pure thermoplastics and therefore fully recyclable.

Cepatex stands for a long-term quality guarantee and professional reliability. The chemical composition of our products remains unchanged, hereby guaranteeing a constant quality and high reliability in terms of processability to our customers.

We particularly care about our environment and the health of our customers. We ensure that our products do not contain components harmful to health as well as air and water contaminants.

We are ISO 9001 certified since 1999

60 to 220 °C

Low

Medium

High

Textiles

Leather

Nonwovens

Synthetic fabrics (PU)

Foams, Plastic (PVC)

No or low emission of VOC

Heat resistance

Dry cleaning resistance

Wet cleaning resistance

Plasticizers resistance

Flexibility at low temperatures

Breathability

Elasticity

Resistant to environmental influences

We offer a wide range of Copolyesters in granular form, to meet the requirements of our customers as best as possible.

Plasticizers-free

Tin-free (fulfills regulations like Oeko-Tex)

No residual monomers (car application)

No volatile components

Our products can contain a small amount of additives such as wax, stearate and optical brightener

We offer a wide range of Copolyamides in granular form, to meet the requirements of our customers as best as possible.

Heat-stabilized

Based on Caprolactam or Caprolactam-free

Manufactured to a great extend from renewable resources

Our products can contain a a small amount of additives such as wax, stearate and optical brightener

We offer a wide range of Polyester Elastomers in granular form, to meet the requirements of our customers as best as possible.

These are types of thermoplastic engineering polymers consisting of rigid and flexible blocks in the same polymer chain. Varying the structure and the size of these blocks it is possible to achieve different properties of polymers. Excellent flexibility, resistance to high temperatures and good chemical resistance combined with high impact strength are the most remarkable features. The full range of polymers includes products with different shore hardness, melting temperatures and application temperature (-50° C to 150 ° C). Shore hardness and flexibility are between vulcanized rubber and traditional thermoplastic polymers. Polyester Elastomers are fully thermoplastic and can be processed as the traditional engineering plastics (Extrusion, blow molding, injection and rotational molding).

Our products are used in a wide variety in the automotive and textile industries.

Moreover they find use in technical areas and industrial processes.

CEPAT AG is a partner of the automotive and textile industry. We are proud to have major players of the automotive and textile industry among our customers.

In the automotive industry our products are used for the manufacture of car trims in thermoforming processes.

Our area of application:

Pillars

Door trims

Headliners

Luggage compartment trims

Dashboards

In the textile industry our products are used for various applications. We serve a wide range of applications, including the usage in the furniture and clothing sector.

Our area of application:

Upholstery fabrics (furniture)

Clothing (collars, puffs, print...)

Shoes

Interlining

Breathable films

In the technical sector our products are used for functional covers.

Acoustic isolation

Heat isolation

Mechanical protection

Barrier-effect

Rotational molding

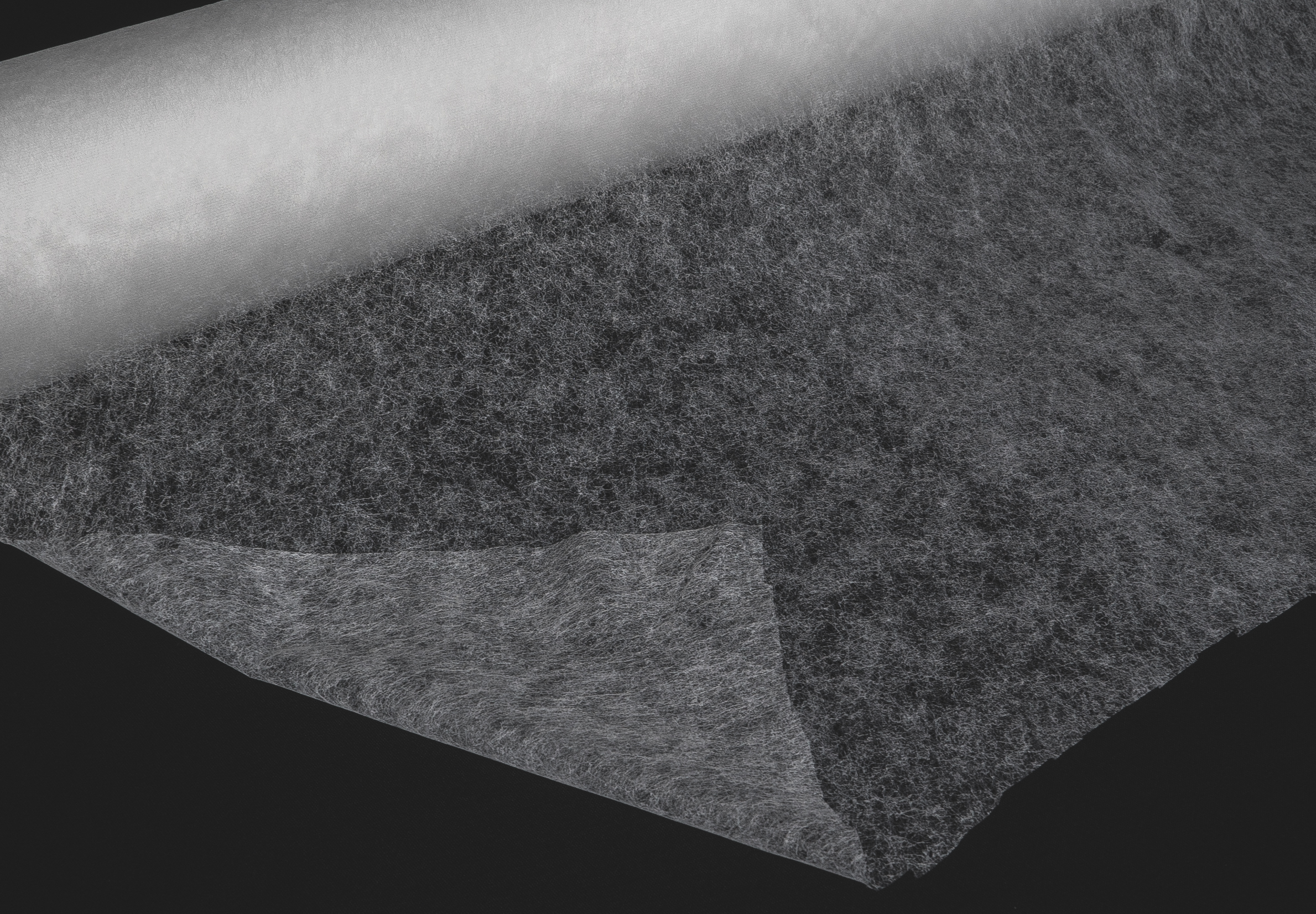

CEPAT AG has many years of experience in the field of lamination and coating technology. The Cepatex granulate is used as basic material for the production of hot- melt powder, webs, films as well as for laminating and coating of various materials.

Our Products are used in a great variety of industrial processes.:

Melt-blown film extrusion

Flat-die extrusion

Melt-blown

Spun-Bond

Melt-Print

Slot Die

Powder scattering

Powder point

Paste point

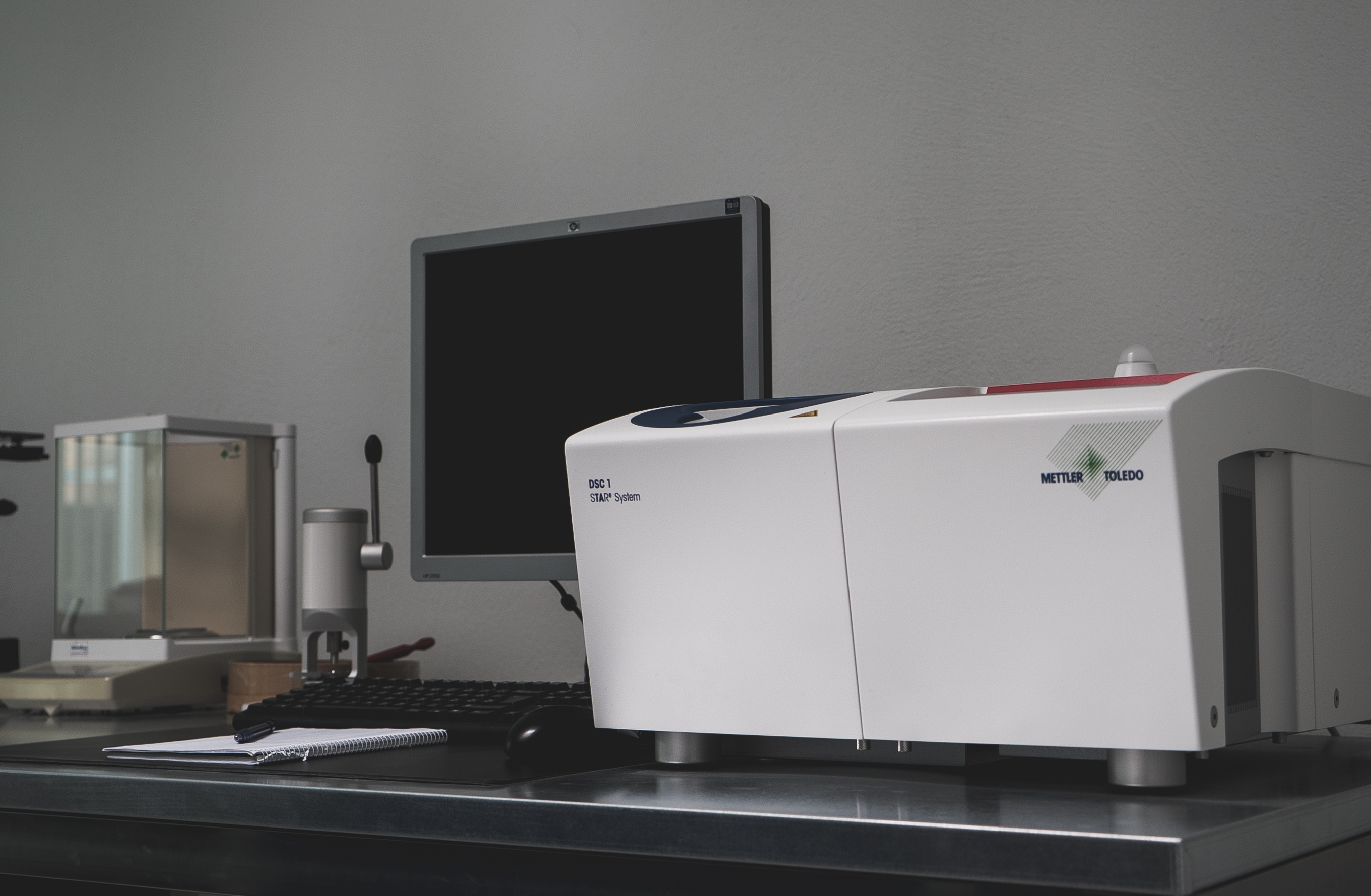

Our Cepatex products are monitored, controlled and tested in production and in-house.

Our Production is equipped with the latest technologies. The online process monitoring and our ISO 9001 certified quality control system ensure to maintain the highest quality level in our products.

Batches are produced in smaller plants in order to remain flexible towards our customers.

Each batch is carefully controlled and only released if it meets our strict quality specifications.

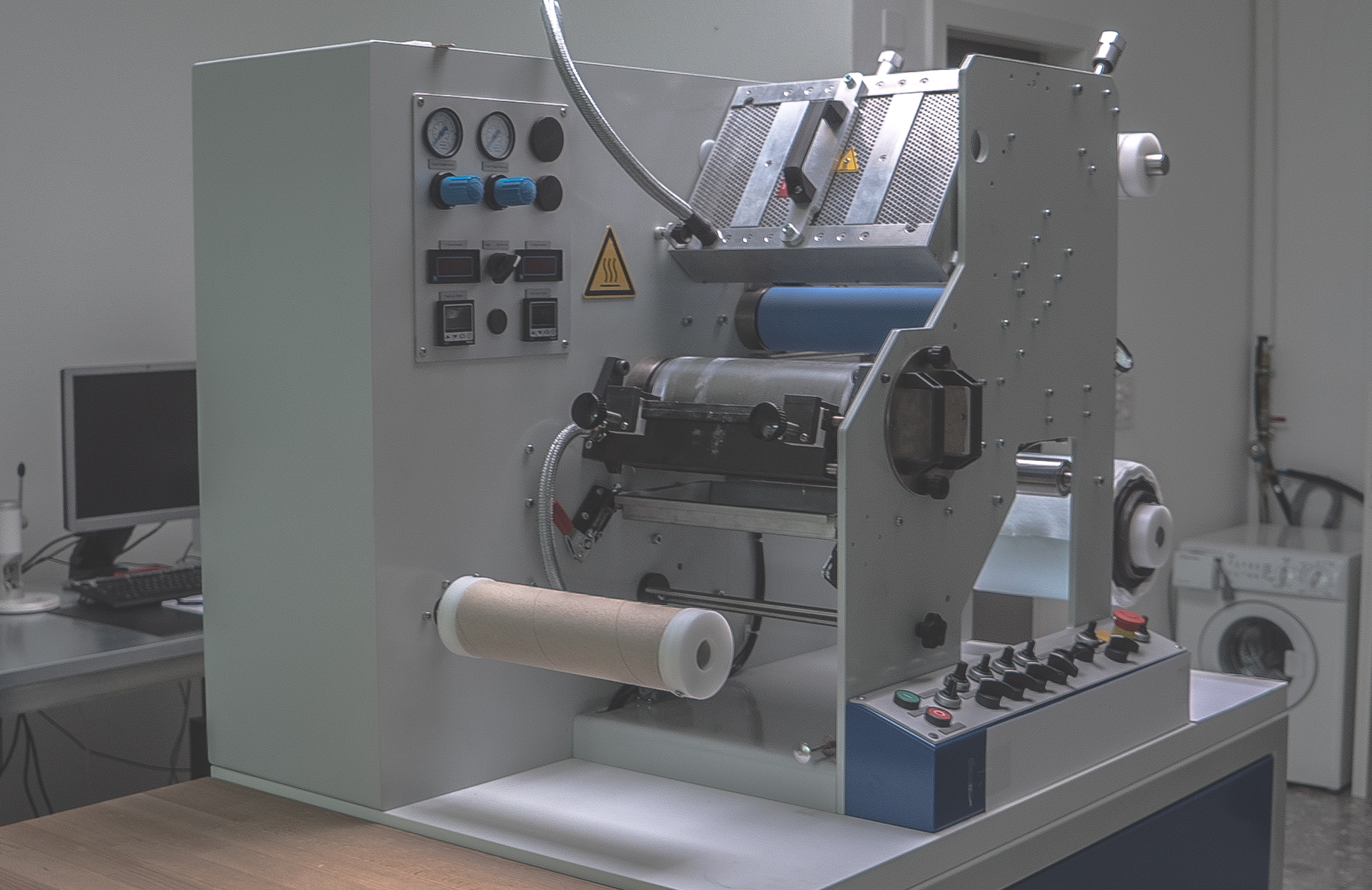

CEPAT AG carries out pilot test for customers to study the feasibility of their projects.

Our customers save time and benefit from our experience in laminating and coating technology.

We test our products in our technical laboratory in Chur.

Coating and laminating trials are performed on our two pilot machines.

Melt-Print

Slot-die-coating

If you have any further questions or want more information about our products, you are welcome to contact us.

We gladly send you brochures and data sheets for our Cepatex products.

Comercialstrasse 22

7000 Chur

Schweiz

Tel: 0041 (0)81 253 77 44

FAX: 0041 (0)81 253 78 72

cepat@bluewin.ch

Copyright © 2018 CEPAT AG